Calorimetric Chambers For Testing Fan Coils And Fan Units - EN 1397

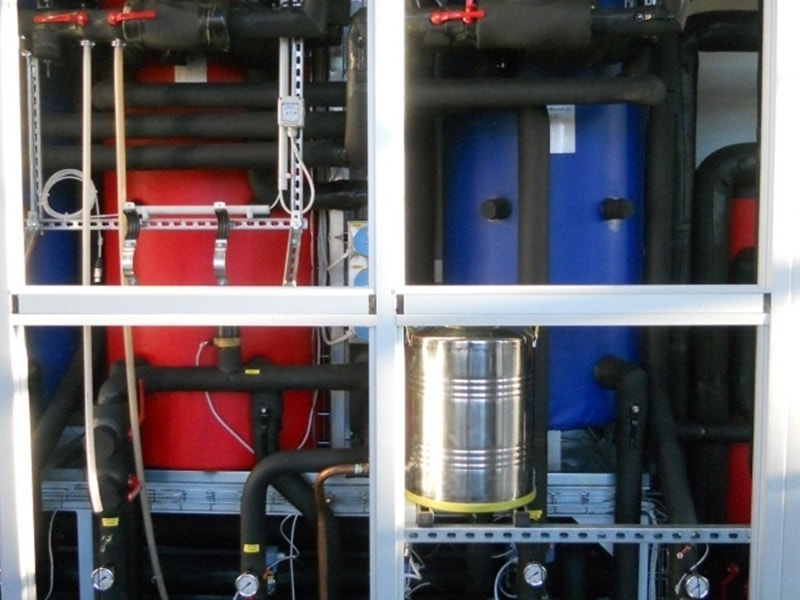

Our calorimetric chambers for testing fan coils and fan units (EN 1397) are designed and built to guarantee the necessary conditions for testing the thermal performance of fan coils and hydronic units that operate with superheated or subcooled water or with water mixtures.

Depending on requirements, we can:

- Incorporate a data acquisition system that generates reports containing vital data about the tests and calculations about the efficiency of the products being tested.

Calorimetric Chambers For Testing Air Conditioners And Chillers - EN 14511 / EN 14825

Our calorimetric chambers for testing air conditioners and chillers (EN 14511 + EN 1482) are designed and built to guarantee the necessary conditions for testing the performance of air conditioners (split and monobloc) and chillers that use electric compressors for heating and cooling.

They are usually built with two chambers:

- One simulates the temperature and humidity conditions of the environment in which the indoor unit is installed;

- The other simulates the temperature and humidity conditions of the environment in which the outdoor unit is installed.

Communication between the two environments is available upon request.

Depending on requirements, we can:

- Incorporate a data acquisition system that generates reports containing vital data about the tests and calculations about the efficiency of the products being tested.

Test Rooms For Air-To-Air Heat Exchangers - EN 308 / EN 13141-7

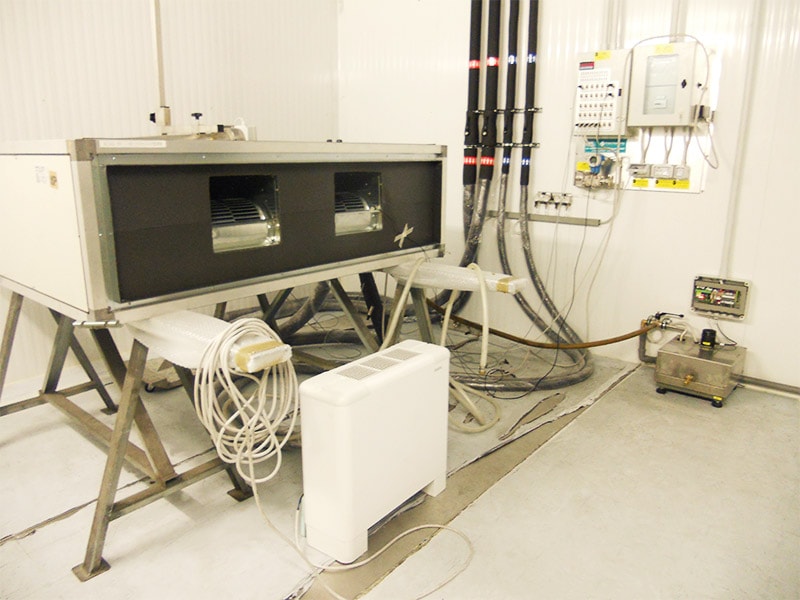

Our test rooms for air-to-air heat exchangers (EN 308 + EN 13141-7) are designed and built to guarantee the necessary conditions for testing the efficiency performance of residential air-to-air heat recovery units.

The space is equipped with a system, which is usually forkliftable, that enables all the tests required by the relevant standard to be performed:

- Efficiency tests;

- Air flow measurements;

- Pressure drop tests;

- Internal leakage tests;

- External leakage tests with positive and negative pressure.

Depending on requirements, we can:

- Incorporate a data acquisition system that generates reports containing vital data about the tests and calculations about the efficiency of the products being tested.